From assuming to knowing

What is FiGS®?

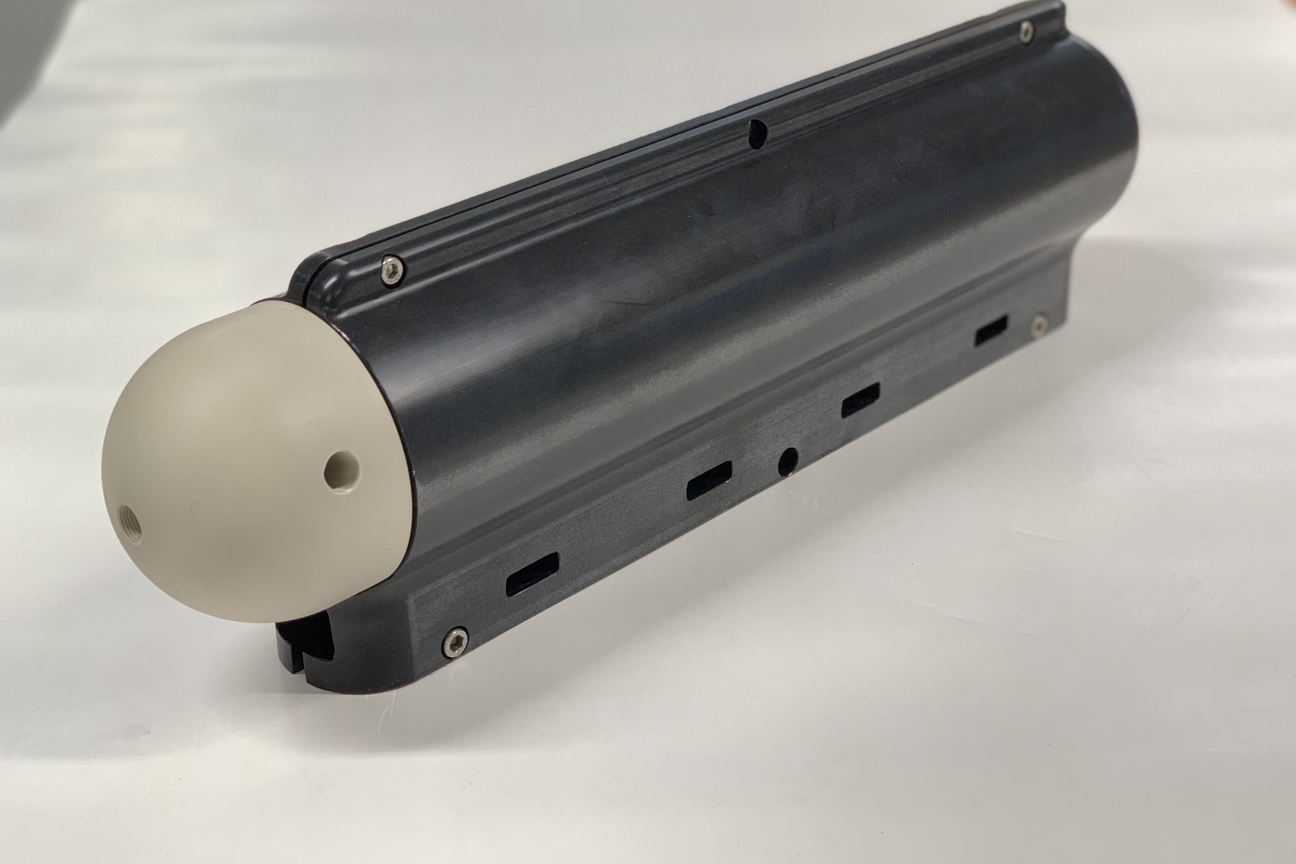

FiGS® is a field gradient sensor designed and built by FORCE Technology, passively measuring the current set up by cathodic protection systems. Traditional field gradient sensors measure a potential drop between two cells (Ag/AgCl) placed with a 50cm distance between, to determine anodic/cathodic activity. These cells will drift over time and require calibration every 1 km pipeline or every hour.

Unlike traditional field gradient probes, FiGS® has cells mounted on a rotating head that eliminates cell drift and calibration issues. The rotating head also provides direction of the electric field; the direction provides relative position of findings and makes the sensors unaffected by variable ROV positions during survey.

Normally field gradient surveys are combined with CP measurements either by contact measurements (stabs) or continuous CP (remote cell CP or trailing wire). Traditional CP measurements require frequent stabs and calibrations, slowing down the process, and may not even be possible if the asset is buried and in areas normally out of reach.

FiGS® provides both field gradients and protection level (potential) in one sensor, without contact. The data is combined with CP modelling to accurately determine life expectancy, anode current outputs and a potential profile.

Changing the course of cathodic protection with verified data and predictions of the future

Instead of just checking that the CP system is working, the FiGS® will allow operators to see how hard each anode is working and thereby calculating life expectancy. It also reveals any currents drain or even defects in the coating. All of this goes for buried assets as well.

This insight has allowed FORCE Technology to kick a few dents into established CP standards and recommended practices. This include verified data on:

- Drain between structures and drain to wells

- Effective steel current density on structures and pipelines

- The effect of conservative CP designs (passivated / inactive anodes)

- The performance of modern coatings and field joint coatings

- CP interactions between new and old installations

3D modelin SeaCorrTM combined with FiGS® data

Paving a safer, faster and greener way for the future

Because the FiGS® is contactless and highly accurate, it allows for inspections using fast AUVs at a safe distance. This is more efficient from both an economic and environmental approach; it uses less resources to get a clearer image, which almost without exceptions leads to fewer replaced anodes. A retrofit performed with FiGS® will instead of relying on design standards ensure a significantly leaner design – from experience typically more than 50 %.

Traditional methods are providing a snapshot status of the CP system, forcing operators to perform CP inspections at fixed intervals (e.g. every 3-5 years), or to do some CP measurements, whenever they are in the area. Since FiGS® provides the life expectancy of the cathodic protection system, it can be used to optimize survey frequencies based on remaining anode life.

The technology has been given the Technical Readiness Level 7, field proven, by several major Oil & Gas operator (BP, AkerBP, Equinor, Shell, Chevron amongst others). FiGS® will play a significant role in reaching their common future vision of remote or autonomous inspections. Even in today’s market where many inspections are still performed with ROV’s, the operational window of FiGS® enables a much higher inspection speed, which significantly reduces the number of vessel days.

Track record:

Pipeline (Buried, exposed, flexible): more than 5 000 km

SPS (Manifolds, x-mas trees, PLEM, PLET): more than 200 structures

Structures (Jacket, FPSO): approx. 30 structures

Areas of deployment:

Norway, Netherlands, UK, Canada, US, Trinidad & Tobago, West Africa, South East Asia, Australia

Statement from BP

“BP has employed Field Gradient cathodic protection assessment on a number of international pipeline and structural inspections. The speed of acquisition aligns with BPs Fast Digital Imaging methodology as well as providing quality assessment of remaining life of asset relating to Cathodic Protection.”

David Page, CP Authority BP/ Eric Primeau, GSE Senior Technology Specialist, BP

Statement from Equinor

“Equinor utilized FiGS sensors on the Norne field in 2018 to survey 11 subsea template structures and 60 km of pipeline over several shorter sections. Mostly flexible, but some rigid pipes. The survey was conducted with a traditional wROV spread that included accurate navigation and multibeam echosounder.

The investment proved to be directly value-creating for the Company. Processed FiGS-data verified ageing subsea assets to be intact:

- Templates well protected, despite some anodes totally depleted

- Flexible pipes had undamaged outer sheats

- Rigid pipes well protected, most anodes working but a handful not in contact with pipe

- Based on this it was possible to prove that subsea assets have technical integrity for a lifetime extension to 2030 and beyond. Increasing productivity and lowering CO2 emissions for Equinor.”

Stein-Inge Sørensen, Principal Engineer Operations Subsea, DPN SUM SAN SHH, Equinor ASA

To learn more, visit: www.figs.no