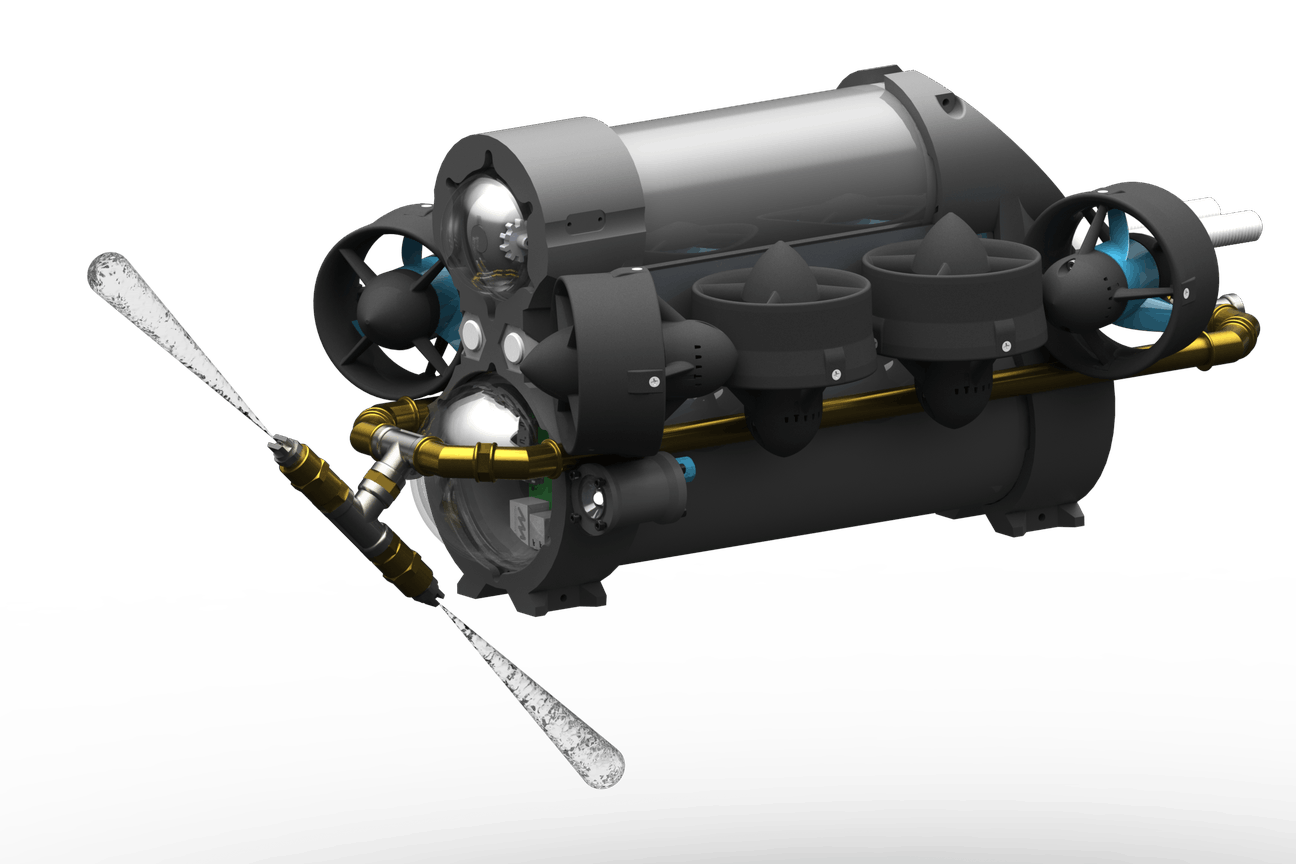

High Pressure Cleaning Mini ROV

The Stinger mini ROV was initially developed for visual inspection inside confined spaces. To make it suitable for cleaning operations, the mini ROV was fitted with two high pressure water jet nozzles. The two nozzles are used to maintain an equilibrium of forces during the cleaning operation – ensuring good stability and maneuverability of the mini ROV.

The mini ROV is a standalone system and don’t have to be integrated into a work class ROV. The mini ROV is manually launched over the side of the vessel, and dives down to the required working depth without any assistance. Once on work location the WROV is used for monitoring the mini ROV – providing a second view for orientation/navigation.

The high pressure water jets are directly connected to a high pressure pump topside on the installation vessel, which is manually turned on and off as required. The mini ROV is connected to a mobile control station topside, which can be set-up anywhere suitable for the operation.

The high pressure water jets are directly connected to a high pressure pump topside on the installation vessel, which is manually turned on and off as required. The mini ROV is connected to a mobile control station topside, which can be set-up anywhere suitable for the operation.

Read more: Suksess for Stinger Technologys mini-ROV

Testing and Verification

To verify the suitability of the mini ROV, the system was tested onshore prior to the offshore operation. The testing included entering a test model of the confined space through a 300mm hole and running the water jet inside to ensure the ROV could handle any turbulence arising. Further testing was done to verify that the water jet on the mini ROV was powerful enough to clean the weld surfaces to an acceptable level. Upon successful test results, the mini ROV was mobilized for the offshore campaign.

Successful Cleaning Operation

The conventional cleaning method for this task was based on a Ultra High Pressure (UHP) cleaning spread with ROV cleaning lances. Due to the challenging geometry of the inspection areas, the angle of the nozzle on the cleaning lances had to be changed multiple times to reach all the areas required. To change the angle of the nozzle, the lances had to be recovered to the deck of the installation vessel.

The conventional UHP spread was used for the rough cleaning inside the confined space, after which the mini ROV was sent in to clean the remaining patches that the lances did not reach. This eliminated the requirement to adjust the nozzle on the lances, and improved the efficiency of the operation.

The achieved surface roughness after cleaning with the mini ROV was better than initially anticipated and the operation was considered to be a great success.