It's Time to Think Differently

Is there anything more insightful than the collective voice of a market? It not only shines a light on trends and strategy but where opportunities exist. Paying close attention to such feedback has illuminated Proserv’s innovation pathway in subsea control systems.

Each year, Kimberlite International Oilfield Research releases multiple in-depth reports, based on interviews with global operators, which represent that voice. In the studies focused on the performance of subsea equipment and service suppliers, the sections dedicated to controls make for puzzling reading.

Many operators have been stuck in a Groundhog Day cycle of subsea electronics failures and replacement, as they bemoan reliability and obsolescence issues. Pulling from Kimberlite’s 2023 and recent 2024 reports reveals that 97% of those interviewed (virtually everyone) expects to replace their controls twice during an assumed 20-year lifespan for a typical well, with the modules the likeliest component to fail.

One in three of those questioned by Kimberlite says subsea control systems need improvement and advancement, while two-thirds of all new installations around the globe are to replace or retrofit an existing legacy system.

Oil & Gas is often labelled a conservative industry, yet it is awash with innovation to extend life and reduce costs. But no-one can argue with what this feedback is telling us – operators are too comfortable with the status quo and cannot think outside the box when it comes to confronting challenges presented by obsolete and unreliable subsea electronics.

It is all too easy to set up integrated contract models and frame agreements – why hunt out the best-in-class when you can just get your tree, controls and umbilical at a one-stop shop? By the time the controls are no longer supported by the original supplier that short-sighted decision will be in the rear-view mirror. But declining efficiencies and unreliable production performance will be staring an operator in the face.

The giant original equipment manufacturers (OEMs) seek to hook operators into choosing their next taxi off the rank. So, when a customer begins to face reliability issues as modules fail, the solution invariably put forward by the OEM is a full upgrade to its next generation system.

In today’s world of protracted lead times, increased materials costs and an ever-growing responsibility to lower carbon emissions, an outcome requiring intensive infrastructure replacement, new topside interfaces and major intervention via vessels and personnel is totally out-of-step.

Many of the majors must open their eyes, follow the lead of agile, creative independents and realise it doesn’t have to be like that. It’s time to think differently.

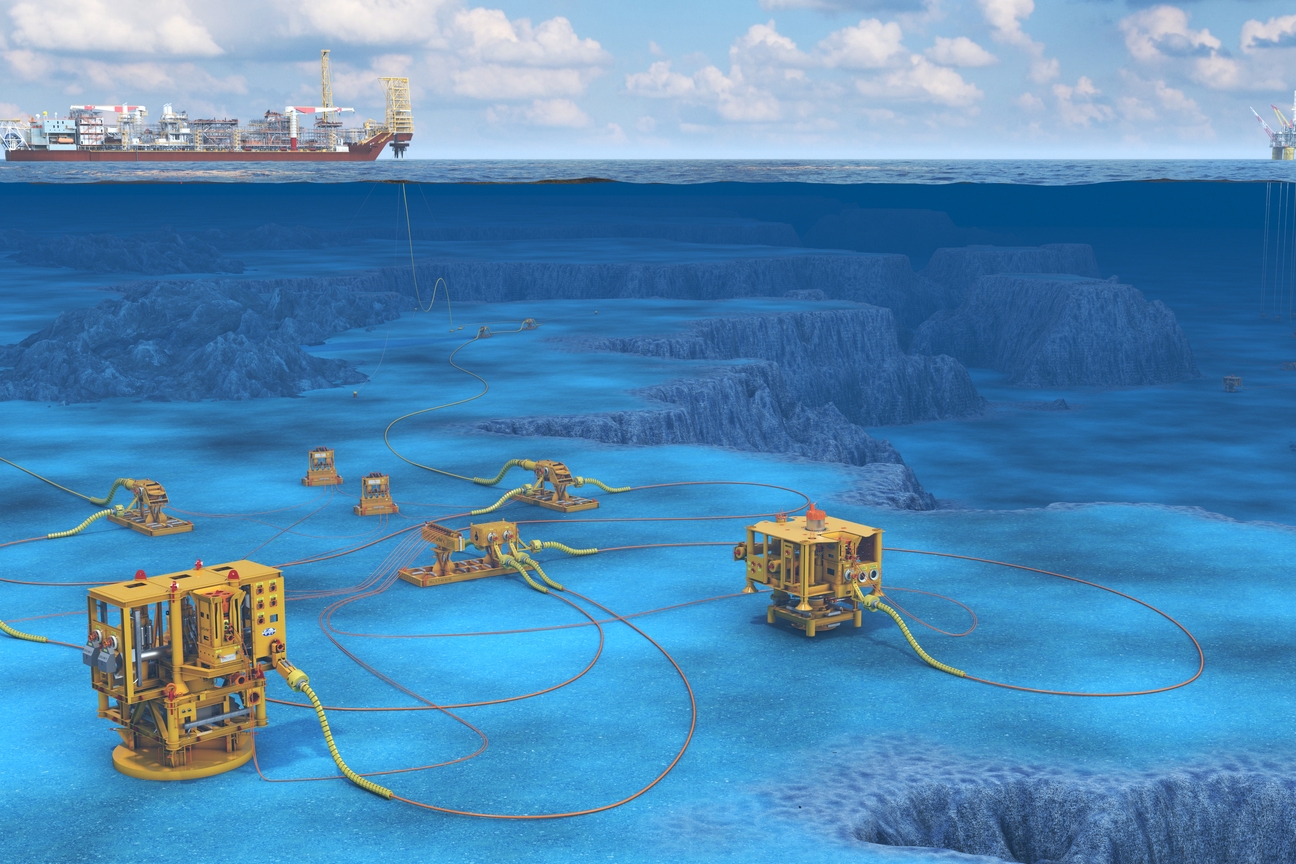

At Proserv, we have engaged insightful market feedback to engineer a unique entirely agnostic solution, called augmented controls technology (ACT), that we have deployed across the globe to unshackle failing subsea fields trapped in a loop of inefficiency. ACT is focused on regeneration not replacement, meaning swifter, targeted interventions, reducing time, cost and footprint.

ACT’s backwards compatibility means it has the capability to coexist with any legacy subsea control system from any OEM. That alone is a game-changer. We can swap out failing subsea electronics modules (SEMs) utilising our own Artemis 2G (A2G) SEM. Surgical cherry-picking and retrofit versus complete removal and replacement.

Not only that, but with our comms speeds and bandwidth, we can extend the offering with added functionality. Our philosophy is minimal impact to maximise outputs. This approach resonates with nimble, forward-thinking operators who recognise how smart technologies can optimise production, shrink carbon footprints and decrease costs.

In Norway, for instance, we have worked closely with OKEA ASA, an operator focusing on mid-to-late oil and gas fields, on its Draugen field. Draugen is a field that has been in operation for 30 years and recently received approval for a further 15 years of operation. OKEA’s modus operandi is to use solutions like ACT to maximum value on existing fields and to unlock further gains. Our shared philosophy and outlook have seen our collaboration on Draugen evolve into an exciting master service agreement.

Adopt a different way of thinking, embrace disruptive, smart solutions and break out of the status quo: such a methodology can reduce costs and emissions, enhance productivity and extend life just as much for the majors as it can for the independents.